Our Filiera

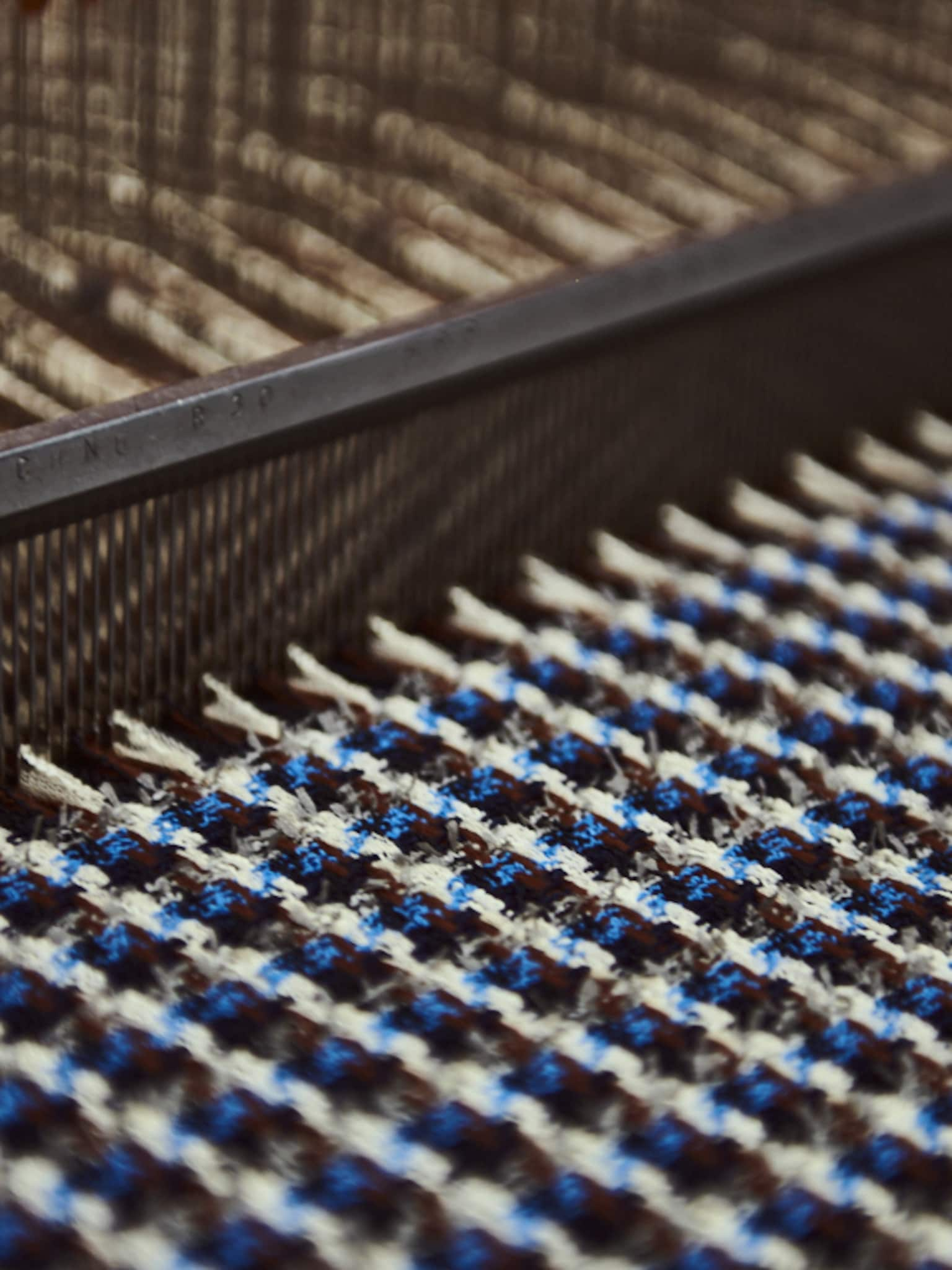

The Ermenegildo Zegna Group is internationally recognized for its unique Filiera, owned and controlled by the Group, which is made up of the finest Italian textile producers fully integrated with unique luxury manufacturing capabilities, to ensure superior excellence, quality and innovation capacity.

Fabric is fundamental to the Zegna Group: it is our essential truth woven into everything we do for over 110 years. Fabric was the bold ambition of the founder to be a force for good in the world. Fabric represents our culture of beauty as far as the Group remains an industrious master of it with an unrivalled manufacturing legacy, forward-looking creativity, and technical and sustainable innovation.

Over the years, the acquisition of historic Italian companies, each specialised in its own product sector, has enabled the Group to create a one-of-a-kind Made in Italy Luxury Textile Laboratory Platform with the aim of producing the highest quality fabrics, while safeguarding the uniqueness of the Italian supply chain in the name of craftsmanship.

Through Lanificio Zegna, Tessitura Novara, Pettinatura di Verrone, Bonotto, Cappellificio Cervo, Dondi, Tessitura Ubertino, Filati Biagioli and Luigi Fedeli e Figlio, the Group relies on a unique platform that acts with a constant quest for creativity, innovation and quality.

Fabric is fundamental to the Zegna Group: it is our essential truth woven into everything we do for over 110 years. Fabric was the bold ambition of the founder to be a force for good in the world. Fabric represents our culture of beauty as far as the Group remains an industrious master of it with an unrivalled manufacturing legacy, forward-looking creativity, and technical and sustainable innovation.

Over the years, the acquisition of historic Italian companies, each specialised in its own product sector, has enabled the Group to create a one-of-a-kind Made in Italy Luxury Textile Laboratory Platform with the aim of producing the highest quality fabrics, while safeguarding the uniqueness of the Italian supply chain in the name of craftsmanship.

Through Lanificio Zegna, Tessitura Novara, Pettinatura di Verrone, Bonotto, Cappellificio Cervo, Dondi, Tessitura Ubertino, Filati Biagioli and Luigi Fedeli e Figlio, the Group relies on a unique platform that acts with a constant quest for creativity, innovation and quality.

Lanificio Ermenegildo Zegna

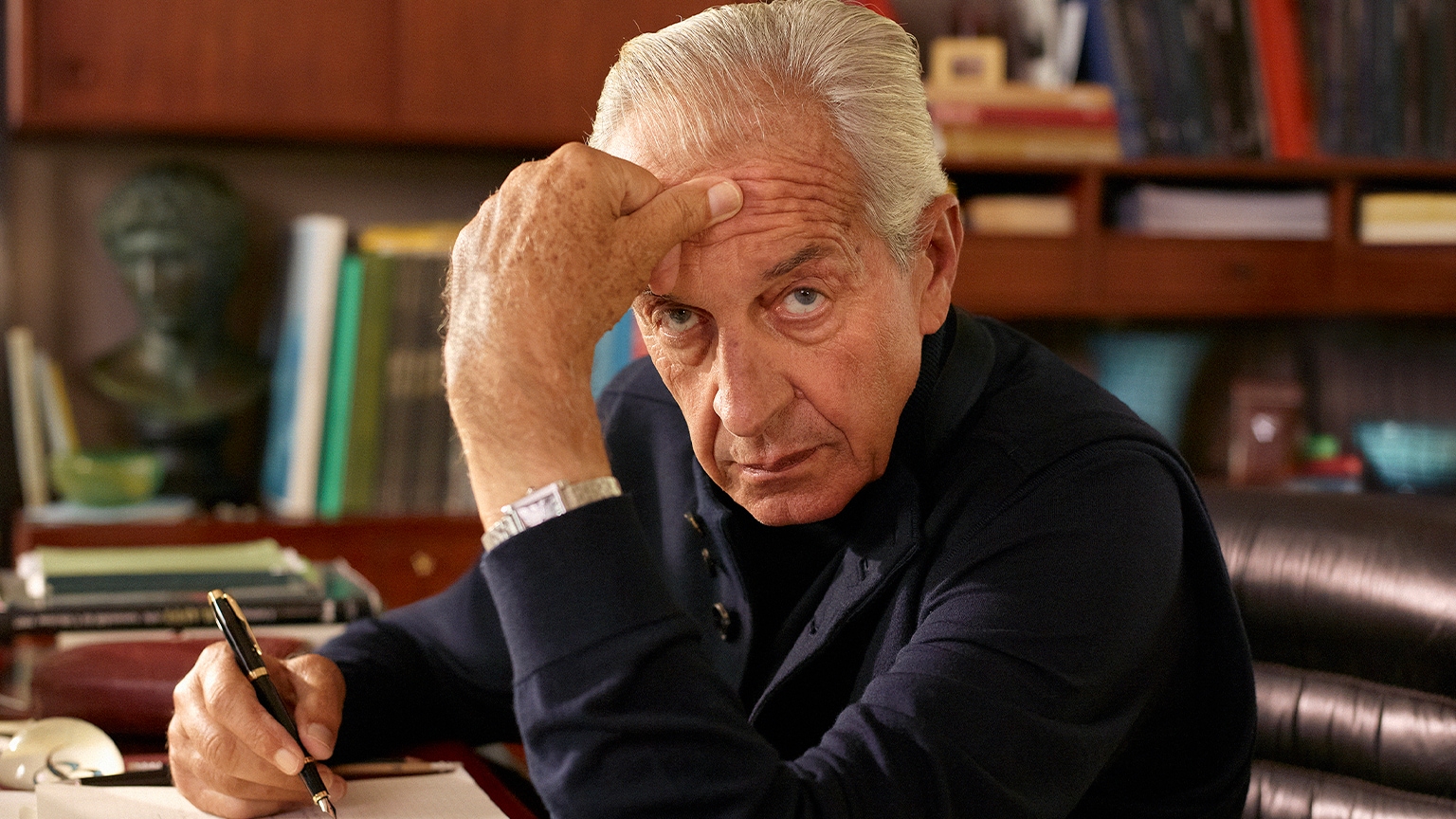

Founded in 1910, the Ermenegildo Zegna Wool Mill is the backbone of the company’s development and is renowned internationally for the world’s finest textiles. Four generations of the Zegna family have led textile success by carefully balancing science with nature and craftsmanship with technology. As a result, the Lanificio Ermenegildo Zegna has pioneered sophisticated men’s fabrics that are lighter, smoother, more refined, and with improved performance and functionality.

The complete production process is carried out by the Zegna Group – from raw material selection to finishing. Located in Piedmont, Northern Italy, the local mountain rivers carry purified water that wash the Zegna Wool Mill’s fabrics and give them a particularly soft finish. Commitment to quality and the use of modern technology to back up artisan craftsmanship is our living tradition, linking past, present and future.

Tessitura di Novara

Tessitura di Novara

Tessitura di Novara, a company specialised in high quality silk weaving, was acquired by the Zegna Group in 2009. The historic Italian manufacturer was founded in 1932 and has since become a leading producer of pure silk and other high-end natural fabrics. Thanks to the unparalleled quality and uniqueness of its textiles, Tessitura di Novara’s customer portfolio includes many of the most important international luxury fashion brands. With its combination of artisan skills and innovative technologies, Tessitura di Novara has been seamlessly integrated into the Luxury Textile Laboratory Platform of the Zegna Group.

Pettinatura di Verrone

Pettinatura di Verrone

In 2012, the Zegna Group acquired shares in Pettinatura di Veronne, to contribute to the maintenance of the sophisticated fabric company and preserve the wealth of knowledge and human resources within the textile district of Biella, where it was founded in 1960. Specialising in the combing of superfine wools, cashmere and vicuña, Pettinatura di Verrone continues to produce remarkably fine natural fibres of the highest quality standards, further enriching the Luxury Textile Laboratory Platform of the Zegna Group.

Bonotto

Bonotto

In 2016, the Zegna Group acquired a majority stake in Bonotto, a fourth-generation textile manufacturer based in Molvena, Italy. Founded by Luigi Bonotto in 1912, the brand celebrates the Slow Factory movement against mass production at low cost, focusing instead on handcraftsmanship and traditional techniques. Bonotto is characterised by the creative and experimental dimensions of their fabrics. Inside the factory, there are over 24,000 works of art from the Bonotto Foundation, which inspire the production processes and make Bonotto an authentic "creative source" of fashion textiles. The brand consists of a style centre devoted to research and development, a weaving and warping plant, as well as a dyeing and finishing plant.

Dondi

Dondi

In 2019, the Zegna Group acquired the majority shareholding of Dondi. Celebrating over 50 years in business, Dondi is a leader in manufacturing high-quality jersey fabrics for men and women, all Made in Italy. Through this acquisition, the Zegna Group not only strengthens its standing in fabrics excellence, but also achieves a sizeable expansion in the specialisation of its own textile supply chain.

Tessitura Ubertino

Tessitura Ubertino

In 2021, the Zegna Group consolidated its Luxury Textile Laboratory Platform with the acquisition of a majority stake in Tessitura Ubertino, a renowned company specialising in high-end fabrics for women, based in Pratrivero, Biella, Italy. Founded in 1981, Tessitura Ubertino is a boutique weaving mill that has been creating premium quality fabrics, such as tweed and jacquard, for over 30 years. Today it is a well-known research laboratory and hub for textile innovation within the global luxury fashion industry.

Cappellificio Cervo

In 2018, the Zegna Group acquired ownership of the historic Cappellificio Cervo, a well-known hattery in Biella, Italy, with over 120 years of history. Cappellificio Cervo, which takes its name from the nearby stream that crosses the Biella area, was founded as a cooperative in 1897 by local master craftsmen who started the path that made it one of the most prestigious worldwide brands in the sector.

The company has still original machinery from the 1800s, which allow it to preserve, unaltered, some of the detailed work methods particularly appreciated by several, prestigious worldwide luxury brands. Traditon and innovation are the key elements of this leading manufacturing company that largely contributed to the crafting excellence of the Made in Italy.

Filati Biagioli Modesto

Filati Biagioli Modesto

In 2021, Zegna Group and Prada Group have acquired the majority shareholding in Filati Biagioli Modesto S.p.A., a company based in Montale, Pistoia, Italy. For over a century, it has excelled in the production of cashmere and other noble yarns and offered superiority in the process of transforming fibres, assuring perfect quality throughout the production process. The Zegna Group and Prada Group share the same vision for this partnership in which know-how is preserved and value is created for the concept of ‘Made in Italy’, all in the name of craftsmanship and innovation.

Luigi Fedeli e Figlio

Luigi Fedeli e Figlio

In 2023, Zegna Group and Prada have reached an agreement to acquire a minority stake in Luigi Fedeli e Figlio S.r.l. Founded in 1934 in Monza, Italy, and now overseen by a third generation of the Fedeli family, Fedeli is recognized worldwide for the excellence of its Made in Italy knitwear and fine yarns.

ZEGNA

Discover more

Thom Browne

Discover more